How do I automate manufacturing data retrieval and reporting for Cost per Unit (CPU)?

June 5, 2013

Manufacturers are constantly faced with the need to maximize profitability while contending with variable manufacturing costs. One of the key measures involved is Cost per Unit (CPU) produced. The CPU is affected by inputs like raw material costs, energy costs, labor costs, inventory costs, and shipping costs. Traditionally, CPU calculations would have been done monthly or quarterly using manually aggregated financial data.

Why Create CPU metrics with real time manufacturing data?

The accuracy of the CPU value depends on the accuracy of your manufacturing data. Every shift is not the same; some shifts have higher labor rates, some have higher time-of-usage energy costs. Some raw materials fluctuate in price. If you create CPU with real-time data, you can better make intelligent, financial based decisions, rationalize SKU’s, and optimize usage of plants, production lines, and shifts. With real-time manufacturing data, you can better understand the impact of the fluctuating costs of inputs. While the benefits of real-time CPU are many, determining CPU from real-time inputs can be a challenge.

Why is it a challenge to create meaningful CPU KPI’s in manufacturing?

Often, the data required for calculating CPU reside in different systems. For example, cost data may be contained in ERP or MES, while operational data, energy usage, and line performance data may be contained in control systems or in specialty databases at the plant. Data from both enterprise systems and manufacturing systems are needed. Time-stamped production data needs to be dollarized using time-based rates. Bringing all of this data together, and properly aligning it, can be technically challenging.

How can I aggregate and report CPU?

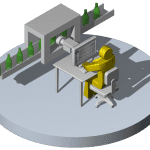

Modern business systems, manufacturing execution systems, process historians and control systems have standardized data interfaces that support transactional data transfer and aggregation. Tools such as OPC for control system to MES data transfer and B2MML and BatchML for MES to Enterprise data transfer, as well as standard structures such as ISA-95 data models, permit the data to be brought from different systems and aggregated together automatically in a meaningful way. Reporting tools, including SQL Server Reporting Services and SharePoint, can present the data in dashboard form and drill-through charts, permitting analysis of data that is only minutes or hours old, as opposed to months or more. Reports can also be automatically shared through corporate e-mail, for those whose responsibility is to monitor and act on the current information.Finally, an appropriate archiving strategy allows the manufacturing data to be used in long-term analysis, or to compare production costs from one plant to another through cube analysis.