OEE Accelerator Solution

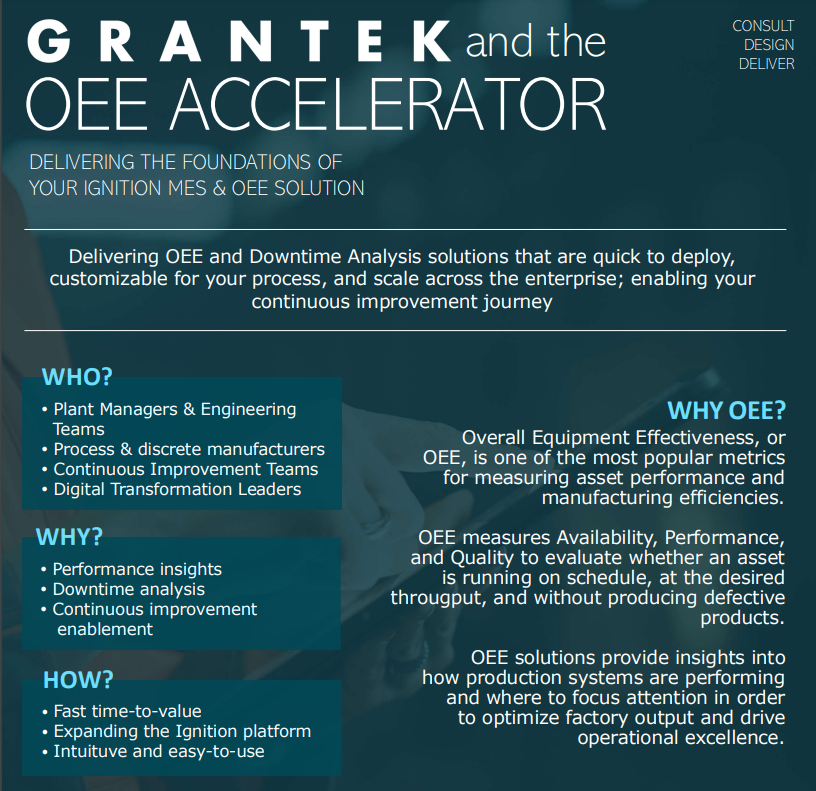

Understanding how your manufacturing systems and assets are performing is one of the first steps to real-time operational insights, identifying opportunities for improvement, and intelligent Smart Manufacturing initiatives. Overall Equipment Effectiveness (OEE) is the essential, industry-standard metric for capturing asset utilization and efficiency.

Implementing systems for tracking OEE and downtime needs to be easy so that you can move onto identifying problems and developing Smart Manufacturing solutions as quickly as possible. Grantek’s OEE Accelerator delivers a strong foundation for Ignition MES deployments with fast time-to-value so that you get immediate results and returns, but it is also designed for flexibility and scalability to adapt to your unique process, business case, and factory environment.

Email info@grantek.com or call 866.936.9509 to learn how your operations can benefit from Grantek’s experience.