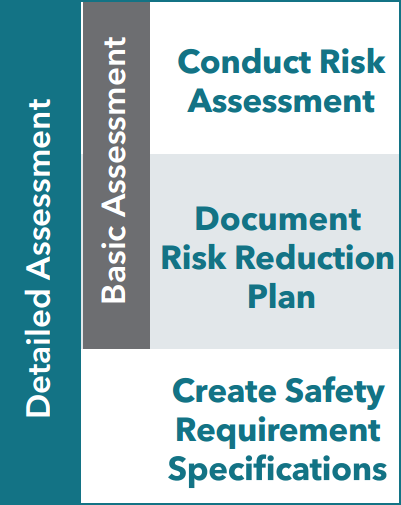

⊙ Risk Assessments (RA) – The process

by which the intended use of the machine, the tasks and hazards, and

the level of risk are determined.

⊙ Compliance Evaluations (CE) – Part

of the risk assessment process where the machinery is evaluated for

compliance to a specific set of regulations or standards. Even though

this evaluation is often completed concurrently with the risk

assessment, it serves a different purpose.

⊙ Risk Reduction Plans (RRP) – The

final part of the risk assessment process where risk reduction

measures and protective devices (inherently safe design measures,

engineering controls, and administrative controls) are collaboratively

selected to reduce the identified risks and compliance deficiencies to

acceptable levels.

⊙ Control of Hazardous Energy Plans (CHE)

– A complementary section to the Risk Reduction Plan (RRP) that is

solely designed to help asses the proper use of the equipment as it

applies to control of hazardous energy. This section helps identify

which tasks may qualify for the minor servicing exception of

Lockout/Tagout as defined by OSHA 1910.147(a)(2)(ii)(B) and includes

an explanation of alternative measures that provide effective

protection and exclusive control.

⊙ Lockout/Tagout Evaluations (LOTO) –

A subset of a Control of Hazardous Plan that only evaluates energy

isolating devices and lockout/tagout procedures to ensure compliance

with OSHA 1910.147.

⊙ Safety Requirement Specifications (SRS)

– A set of design and performance requirements for implementing the

risk reduction plan. The SRS is often considered part of “preliminary

engineering” and is intended to assist in the execution of a capital

project. The SRS is generated off-site after the completion of a risk

assessment and acceptance of the proposed risk reduction plan.

⊙ Budgetary Estimates (BE) – A

preliminary budgetary estimate (+/-30%) for implementing all elements

described in the risk reduction plan. The purpose of this budgetary

estimate is requesting an allocation of funds. A formal proposal will

need to be produced to clarify all assumptions and exclusions before

any remediation can begin.

⊙ Site Surveys (SS) – High level

overview of a large grouping of equipment or an entire facility to

help prioritize where additional safety efforts may need to be

applied. This typically is a 1-3 page report ranking equipment by

overall risk, level of deficiency, and estimated cost to remediate.

⊙ Annual/Bi-Annual Safety Audits (AA)

– Regularly scheduled audits that usually occur after a machine safety

remediation project to ensure no new hazards have been created and all

safeguarding solutions are still performing as designed.