Setting Up for Digital Success: How Greenfield Global Worked with Grantek and Alizent to Undertake a Complete Technology Landscape and Digital Transformation Assessment and Investigation

June 3, 2022

Challenge

Greenfield Global is a privately held leading producer and supplier of high-value, mission-critical raw materials, ingredients, and additives that are vital to businesses and integral to a lower-carbon economy. From their inception in 1988, Greenfield Global has grown from a single plant in Tiverton, Ontario to a global leader with manufacturing and packaging facilities in the US, Canada and Ireland that reach the entire world. Greenfield Global owns and operates four distilleries, three specialty chemical manufacturing and packaging plants, and two next-generation biofuel and renewable energy R&D centers. This integrated model enhances supply chain transparency, quality control and custom formulation development. To support growth, Greenfield Global undertook a technical and digital transformation in order to streamline operations, reduce costs and deliver a more enhanced customer experience.

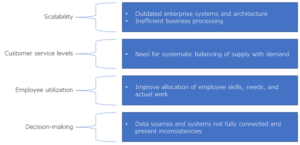

Fig 1.1 – Incumbent Process

This assessment identified a need within their organization to better capture a variety of device datapoints such as tank levels, flows, and temperatures. These datapoints will be sent to their corporate AVEVA PI server and will provide critical feedback into their ERP system allowing the organization to meet regulations, save time, avoid data entry errors and overall be able to make decisions in real time. A central risk was in the form of regulatory violations, violations that could lead to fines, excessive audits and even plant shutdowns. To remedy this, and modernize operations, Greenfield Global engaged Grantek and Alizent to develop, design and deliver a complete IoT-focused data management solution. Grantek and Alizent also conducted an automation discovery to determine the system requirements and to deliver a preliminary high-level architecture design.

Solution

Early in the engagement, Grantek, Alizent and Greenfield Global identified a main driver of these improvements as Regulatory Compliance, as failing to meet regulatory obligations could potentially result in a plant shutdown. It was determined that implementing the AVEVA PI System would put Greenfield Global in a position to improve operations, while satisfying regulatory compliance needs. The AVEVA PI solution provided visibility that helped maintain regulatory compliance, while also capturing production data and tracking that could be used to improve production as well as making data available to regulators if needed. Additional benefits of the AVEVA PI solution will include better forecasting, since this solution could be integrated with Greenfield Global’s ERP in the future.

Alizent and Greenfield Global foster a very good relationship that started in 2019. Alizent has a deep knowledge in PI System, with the specificity of either partnering with technology vendors or custom building its own solutions.

Knowing Grantek’s strong expertise in high-value automation systems, Alizent proposed to pool their complementary skills to answer Greenfield Global’s challenge.

Results

Grantek supplied a report of findings coupled with high-level plant architecture drawings identifying all control panel, device and connectivity requirements for each device type identified as being critical for data collection. This allowed Greenfield Global to obtain high-level project pricing and Alizent to design, implement, and install a new AVEVA PI data analytics platform.

The solution Grantek delivered ensures that critical process data is automatically captured from critical assets. Alizent has integrated the PI system in a way that minimizes the learning curve for Greenfield Global. In addition, Alizent created a user-friendly AVEVA PI Asset Framework structure to facilitate instantaneous ownership of the tool in the plants by operators who were up building displays within minutes of the initial deployment.

This common work between Alizent and Grantek allows for the local plant operations team to monitor the data and quickly make meaningful decisions that help improve plant operations. In the future, this will also reduce the opportunity for operator data entry errors, resulting in an improved supply chain process and allow better visibility and reporting throughout the process. This solution also ensures there is better data reconciliation to improve regulatory compliance. Leveraging automation, through this solution, will eventually optimize Flow distribution and ultimately will increase line speeds. With a long-term vision, Alizent and Grantek also created a list of automated data points and a high-level sustainable data infrastructure that can easily scale as new assets are integrated into the operations, setting up Greenfield Global for future success.

The next steps for this project will involve implementing MES capabilities that could create an estimated savings of 2,250 labor hours, per year. This possible future implementation could also create a solution that removes much of the labor intensive, and reactive, steps that are needed in the incumbent process.

In parallel, Greenfield Global is also considering further integration between AVEVA PI and their new Dynamics 365 ERP which would allow Greenfield Global to leverage cloud-based applications. This would create the best possible environment for the AVEVA PI solution Alizent integrated to succeed. This solution could greatly increase visibility, allowing Greenfield Global to make better, and more informed, decisions on the plant floor and across the enterprise.

Alizent and Grantek will continue to combine their expertise. Alizent and Grantek have deep experience in not only developing system requirements, but also providing high value device connectivity through a wide variety of technologies. Grantek’s agility in this space helped ensure prompt delivery of this customized IoT-focused data management solution across stable architectures. Alizent has a deep knowledge of the AVEVA PI System and has a very good understanding of asset-intensive industries’ challenges. They work intimately with customers to deeply understand their stakes and value chains, committing to the daily operational performance of the solutions. All this set Greenfield Global up to achieve operational success.

This solution is a great example of Greenfield Global, an engaged client, working with Grantek and Alizent to improve aspects of their operation. Setting them up for success at the plant level, enterprise wide and in the event of regulatory compliance audits.