Automated Storage Retrieval System

November 14, 2018

Overview

Grantek recently assisted a longtime client who produces baked goods. The client was performing a major upgrade for security reasons. While they were upgrading their SAP system, they decided to add additional information reporting capability at the same time. It is not uncommon for data communication system upgrades and interface customizations to arise from other upgrade/modernization or expansion projects being completed at a manufacturing facility, when a need or opportunity for improved system interface is identified.

Challenges

The customer wished to integrate the bakery’s inventory system with an Automated Storage Retrieval System (ASRS) that manages the shipping and distribution of the palletized bakery products. Grantek worked to integrate the ASRS system with the facility’s SAP system in order to track the entire process from raw materials coming in all the way to truckloads of finished product leaving the warehouse.

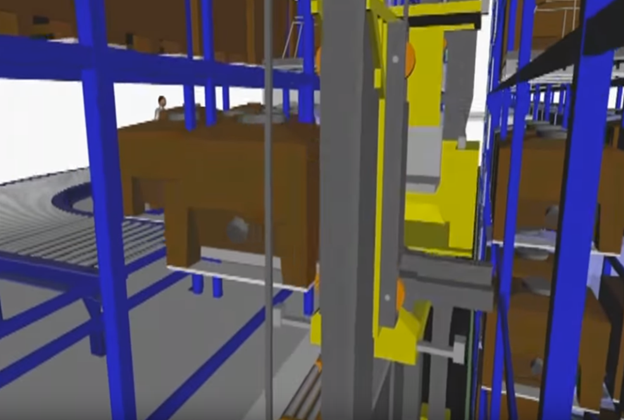

The ASRS takes product from the end of the production line and stores it on racks in a 10-level warehouse. The facility is completely automated and uses cranes to move product into and out of the storage areas for shipment of orders to end customers. The data collected allows tracking of inventory to minimize waste by ensuring that the date-coded bakery products are shipped out in in time.

When a pallet is received in the ASRS, the product information is sent to the SAP system. The system tracks whether it is a new pallet or a quality control sample pallet being returned to inventory after Quality Control (QC) activities are complete. When a QC lot is pulled, the system identifies it as such and tracks it so the facility knows when it was returned to inventory and where it is re-stored. The ASRS data messages inform the SAP system what the product is, and where it has been stored. The product Best By date is calculated from it production date and passed up to SAP.

When the end customer places an order, the SAP system notifies the ASRS of the order. The ASRS knows where each product is stored, pulls the inventory needed for the order, and sends it to be loaded onto trucks for shipment to the end customer. The ASRS uses the balanced by specific product stocking requirements in order to minimize waste. The ASRS also minimizes movement of the product going to the trucks. The warehouse task order tells the ASRS the truck loading dock door where the completed order must be moved to for shipment. The ASRS conveyor system directs the pallets or the order to the spur for the proper truck. When the order is filled, the system communicates to SAP that the ordered product has been moved to the loading point and is ready to be shipped.

Solutions

This customer used a standard SAP library to manage the Communications layer. Grantek worked with the customer to define the information needed for production and for placing orders. Grantek worked with the customer to define all interfaces for data. This project required seven interfaces to be standardized for SAP and ASRS systems. Grantek also ensured system reconciliation to account for discrepancies that occasionally arise between the two systems in the event of human interaction and equipment failures.

To help ensure a trouble-free implementation, Grantek also designed and helped conduct simulated testing to provide comprehensive coverage of normal operations and failure scenarios. Grantek assisted the customer with the commissioning phase to bring the system online.