Agile MES for Smart Manufacturing Success

January 22, 2023

What does MES do?

Manufacturing Execution Systems (MES) are a critical component of a modern manufacturing plant’s technology stack, but it is also a space where many industrial companies struggle to implement, scale, and realize the full potential of their investment.

Click here to download the whitepaper.

MES can be responsible for a variety of functions including, but not limited to:

– Connecting business systems and manufacturing systems

– Scheduling production and work orders

– Conducting performance analysis and calculating KPIs

– Constructing traceability and genealogy information

– Hosting quality test interfaces and paperless forms

– Generating dashboards and reports

– Enforcing work procedures and processes

The Value of MES

Manufacturers that successfully implement MES cite benefits and value from:

– Reduced reporting latency

– Improved product quality

– Improved regulatory compliance and traceability, and less manual efforts to generate compliance data

– Improved and consistent visibility across various sites

– Reduced cycle times

– Improved asset utilization and performance

– Improved supply chain collaboration

– Reduced labor costs

The Challenge of MES

While the benefits from MES are clear and lucrative, successful implementations can be a challenge. A successful MES must:

– Provide clear and tangible benefits for various stakeholders in production, maintenance, quality, inventory, supply chain, and management

– Apply to your specific manufacturing process, business goals, metrics, and culture

– Communicate across both IT and OT networks to interface with business systems like ERPs and manufacturing systems like SCADAs and PLCs

– Appeal to and be easy-to-use for both office-users and plant-floor-users

– Rely on complete and high-quality data from automation systems, accommodating for various levels of maturity and legacy

Common MES Missteps

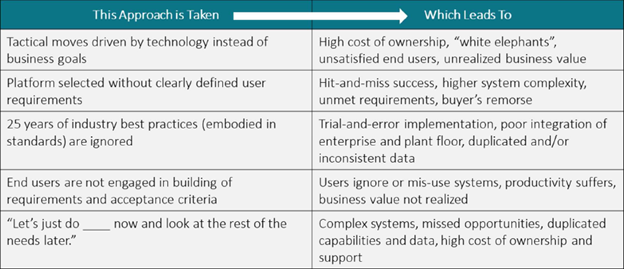

Over the past 20+ years of implementing MES solutions, Grantek has identified some unfortunately common missteps and strategies that can lead to failure:

A New Approach to Address Common Challenges

Essentially, an MES must bridge the gap between the OT/manufacturing world and the IT/business world. The manufacturing space is accustomed to waterfall-style project management techniques that require significant up-front design and are well-suited for integrating high-cost physical assets like new machines and production lines. However, the IT world has found more success with iterative management principles that focus on quick-wins, tight collaboration with end-users, and frequent feature updates to continuously add more value to the system.

As MES software must work with both the IT and OT spaces, it makes sense that MES implementations should borrow from the best practices of both worlds as well. At Grantek, we assert that MES implementation projects have much higher success and adoption rates when they follow an iterative design strategy like Agile/Scrum. Some waterfall-management principles still apply, like understanding the business goals and vision up-front, and a dedicated commissioning and production support phase for major deployments. However, the design, development, and testing of an MES solution can see significant benefits from the collaborative and iterative principles of Agile management.

Grantek’s Agile MES Strategy

Grantek has been developing MES solutions for over 20 years, and the most successful projects are the ones that focus on collaborative design, fast time-to-value, and iterative improvements based on user feedback.

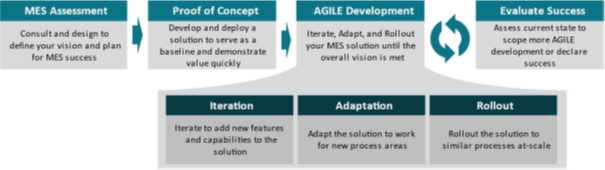

Our approach, summarized in the graphic above, starts with an MES Assessment phase to define the overall vision, understand the technical landscape, collaborate across stakeholder groups, and define objectives for a Proof of Concept. The Proof of Concept phase is intended to demonstrate that the MES solution can deliver on the vision and starts delivering useful tools to your team quickly. Then we go into multiple Agile Development and Evaluation phases to enhance the solution and apply it at a larger scale until your overall vision has been achieved and the program is a success.

Following this process reduces overall risk on the project, delivers valuable solutions to your team quickly, and fosters collaboration to improve cultural buy-in. Grantek focuses on people, process, and technology to deliver game-changing Smart Manufacturing and MES solutions that give your business a competitive edge.

Phase 1: MES Assessment

Understanding the vision, objective and scope for the entire project is essential to delivering a scalable solution that satisfies the end goal. Grantek’s MES Assessment analyzes your people, process, and technology to determine the best approach for the design, implementation, and adoption of the MES solution.

This process provides a roadmap for the early phases of MES development, builds a collaborative relationship between stakeholder groups and the Grantek team, identifies potential gaps and

infrastructure projects that will be required to support the overall vision, and defines an achievable set of objectives for the next phase: the Proof of Concept.

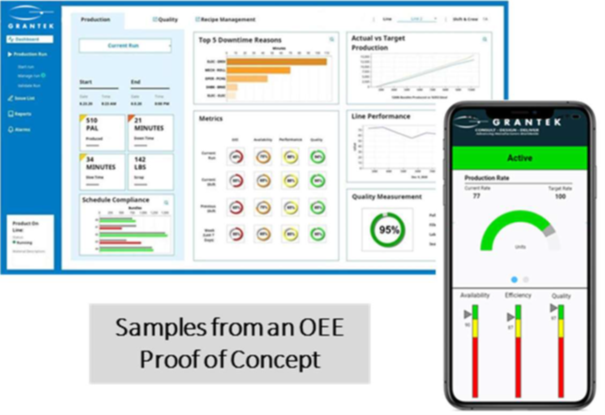

Phase 2: Proof of Concept

The Proof of Concept phase is designed to provide a solution that demonstrates value, establishes confidence in the overall approach to MES, and justifies the next phases of investment and development. Based on findings from the MES Assessment, we collaborate and select a set of high-priority requirements to be developed for a production area. Examples could include Production and Performance Reporting on a Packaging Line, or Paperless Quality for a Mixing Area. This approach allows for key decision points throughout the process to best determine the next course of action, thus preventing a high-cost solution that ultimately does not meet the needs of the customer. This phase does include the solution being deployed on-site and connecting to real-time data. The goal is to provide something that can be used and is useful by your team to get user buy-in and start collecting feedback.

Phases 3+: Agile Development and Evaluations

Once the Proof of Concept is complete, we move onto an Agile-inspired process to improve and implement the MES solution to scale until the overall vision is achieved. For each phase, we scope

system Iterations, Adaptations, or Rollouts to deliver selected systems updates and features on an agreed-to timeline. Once the updates are complete the system is evaluated and mutually determine if more Agile Development phases are necessary, in which case the next phase is scoped, or if the solution is successful.

Agile Development phases are described in three categories:

Iteration – To iteratively add features and improve the existing system. For example, adding Paperless Quality to an existing MES that focused on Production Reporting.

Adaptation – To adapt the system to a new process. For example, applying an MES solution designed for a Packaging area and applying it to a Mixing process.

Rollout – To rollout the MES solution at-scale to numerous similar processes. For example, applying an MES solution from Packaging Line #1 to 20 similar packaging lines.

Each of these phases has similar deliverables and updates the MES solution to meet the new requirements.

Why Grantek?

Grantek, like most MES solution providers, understands the value of delivering systems designed to meet specific business goals, is comfortable working with both the IT and OT space, and has a history integrating factory-floor automation systems to support Smart Manufacturing programs. What sets us apart is our Agile approach and how we use it to start strong using out-of-the-box software capabilities that evolve to meet your specific business needs and processes over time. This is how we deliver solutions with fast time-to-value, low risk profiles, and the cultural support and buy-in of your team; enabling your business to attain its Smart Manufacturing goals. We have found that the most successful MES projects are the ones that account for not just the technology, but also the people and processes that drive adoption, change, and value in your organization.

Grantek also works to set ourselves apart through our technical and business community engagement. Grantek is actively involved in leadership positions and industry associations such as MESA International (www.mesa.org) , the International Society of Automation (ISA, www.isa.org), International Electrotechnical Commission (IEC, www.iec.ch), and the Control Systems Integrator Association (CSIA, www.controlsys.org) to shape the best practices of the industry while benefiting our clients with real world expertise. Our MESA Recognized Practitioners help you develop your strategic road map by applying the best practices and standards endorsed by those organizations. You receive the benefit of over 30 years of industry experience and learnings.

Grantek’s Smart Manufacturing Solutions

Grantek’s Smart Manufacturing team is dedicated to keeping up with the leading edge of Industry 4.0 and Digital Transformation solutions. We bring this knowledge to our customers every day to make them more innovative, integrated, and informed so that they can beat their competition, leverage the full value of their assets, and deliver life changing products to market.

Our team of thought leaders, developers, project managers, consultants, subject matter experts, and partners can help your manufacturing business to realize the promise and value of Smart Manufacturing through Agile MES and our other services and solutions, including:

– Industry 4.0 Consulting and Roadmapping

– Advanced Analytics, powered by Seeq

– Smart Manufacturing ROI Development

– MES Maturity Assessments

– Industrial IT services

– Label verification programs

Next Steps

If your Operations, IT, Engineering or C-suite staff would like more information about Grantek’s Agile MES consulting and implementation services, please email info@grantek.com. Our Strategic Initiative consultants and Subject Matter Experts can also provide insights into potential improvements to your network infrastructure and cyber security, and our Automation and Systems Design teams are ready and able to assist with implementation and integration.