Compliance and Quality Control in Food & Beverage with Grantek’s Label Verification Solution

March 22, 2023

The food industry is one that requires strict adherence to regulatory compliance and quality control measures. Moreover, the slightest negligence in these areas can lead to severe foodborne illnesses and product recalls, which negatively affect both consumer trust and brand reputation. As a market leader in providing industrial automation solutions, Grantek is well-equipped with the capabilities and CSIA certification to address the challenges faced by the food industry. In this whitepaper, we will explore how Grantek’s Label Verification Solution offers food manufacturers an innovative and effective way to ensure regulatory compliance and quality control while enhancing overall efficiency.

Click Here to download the Whitepaper.

Automated Product Validation using Real-time Live Images

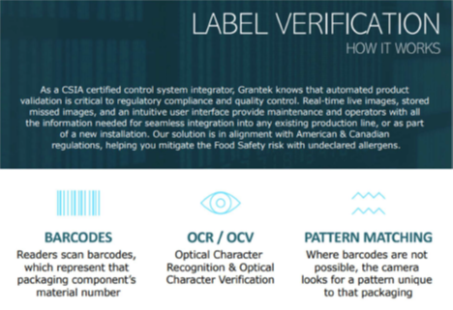

Real-time live image validation technology enables automated inspection of product labels and packaging by capturing high-resolution images and processing them with intelligent algorithms. This method of validation offers numerous benefits over traditional validation methods, such as manual inspection or sampling techniques. By automating the product validation process, food manufacturers can significantly reduce human error, increase efficiency, and ensure accurate label verification at high speeds.

Coordinating Enterprise-wide Rollouts for High Standards

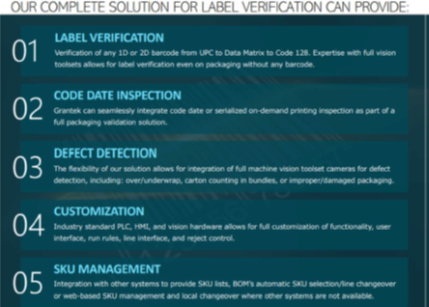

Maintaining uniform quality standards and regulatory compliance practices across multiple production sites can be challenging for food manufacturers. However, with Grantek’s Label Verification Solution, companies can streamline the implementation of these processes within their facilities. Grantek has extensive experience in coordinating enterprise-wide rollouts of automated solutions, ensuring smooth integration and adherence to the relevant regulatory compliance requirements. This coordinated approach reduces production downtime and minimizes the risks associated with compliance discrepancies across different sites.

Compliance and Quality Control with American and Canadian Regulations

Grantek’s Label Verification Solution is designed to meet food safety and quality control regulations enforced in both the United States and Canada. These regulations require manufacturers to prevent risks related to undeclared allergens in their products, a concern that can be effectively addressed by the system’s real-time live image validation technology. By deploying this solution, food manufacturers can confidently ensure that their products comply with the regulatory requirements while minimizing potential risks associated with undeclared allergens.

Customization and Flexibility offered by Grantek’s Solution

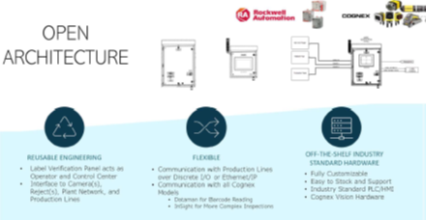

One of the most significant advantages of Grantek’s Label Verification Solution is its flexibility and customization capabilities, ensuring that a minimal loss of plant footprint is experienced during the implementation process.

The system employs PLC, HMI, and vision hardware, which can be tailored to address the specific functionality requirements of a facility. Additionally, the customizable user interface, run rules, line interface, and reject control options enable seamless integration into existing production lines.

MES Integration

Incorporating MES system integration into your production process can greatly enhance efficiency and streamline operations. Imagine having automatic SKU selection at your fingertips, resulting in quicker and more accurate inventory management. Alongside this, you would have the added benefit of historical reporting, providing valuable insights into past performance and trends. To further ensure product quality, cutting-edge defect detection can identify faulty items, while code date inspection keeps track of expiration dates. Combining these features simplifies your workflow, allowing you to focus on improving and growing your business.

Compliance and Quality Control Conclusion

The adoption of automated solutions, such as Grantek’s Label Verification Solution, is crucial for ensuring regulatory compliance and quality control in the food industry. This system not only addresses the stringent food safety regulations enforced in the United States and Canada but also offers a customizable and flexible solution that minimizes production downtime and enhances efficiency. By integrating such innovative technology into their operations, food manufacturers can mitigate risks associated with non-compliance and maintain a strong reputation for delivering safe and high-quality products.