Automated Storage and Retrieval Systems for CPG and Food & Beverage

June 5, 2019

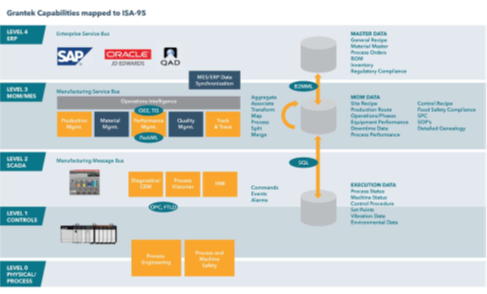

Grantek’s extensive experience as a systems integrator in the food and beverage manufacturing industry provides our clients with a unique edge in the development and upgrading of automated storage and retrieval systems (ASRS) and automated guided vehicles (AGV) commonly used in warehouses. Grantek’s Smart Manufacturing Practice has developed a simple, open-source solution for controlling the ASRS equipment and interfacing it to the facility’s SAP or another enterprise resource planning (ERP) system.

Click here to download the Whitepaper.

Customers with older ASRS systems will benefit from engaging Grantek to design and perform an upgrade. We understand that each site and system is unique and will require an understanding of custom requirements and a plan to address them in the design.

We have extensive knowledge and experience with SAP data structures and we have the programming expertise necessary to allow use of open-source, nonproprietary solutions that simplify system

installation, upgrade and maintenance. We can help you construct a new ASRS or upgrade to an efficient, open-source system that makes use of off-the-shelf hardware and simplifies ongoing

maintenance tasks going forward.

Automated Storage and Retrieval Systems Process Overview

Typically, pallets of finished goods arrive at the warehouse. The Grantek system scans the pallet and pulls out all of the necessary product data (SKU, Line Number, Time Stamp, Shift, Production or Expiration Date), a label is applied to the pallet with a 2D barcode unique to that pallet. The label encodes product data as well as the date of arrival. The product expiration information is this calculated via the ERP system. The pallet label also includes expiration information to help ensure that the warehouse is stocked to maximize efficiency for first-expired, first-out distribution to end customers. Approaching expiration dates are managed by the ERP; in many cases if product gets too close to the expiration date to sell, the ERP system can pull that product for orders or allow for Donation orders to prevent waste of expiring product. This ensures local community organizations can benefit from a donation of safe, quality food that just happens to be close to the sale expiration date.

In addition to the product information, the pallet label also tracks the pallet case count, time shift when product was produced, and its location. Grantek can customize the parameters to be included on the label based on the facility’s needs. The pallet information is then sent to the facility’s ERP system. The system software utilizes a variety of algorithms to direct the pallet to the appropriate aisle and crane in the warehouse. The desired location is sent to the warehouse cranes which load the pallet into the specified location.

When a customer places an order, the ERP system sends the order information to the warehouse. Grantek customizes the facility’s software to create a function that retrieves the desired number of pallets that comprise each product in the order. The system then updates the status of the pallets’ location, and the pallet is moved to the loading dock for shipment to the customer.

System monitoring is performed at the plant level; while the Grantek warehouse control system operates at the warehouse level. The ERP system governs product flow only, but not facilities

management or monitoring.

For products labeled to show production date instead of expiration date, Grantek programs the system to calculate the expiration date based on product expiration information obtained from the ERP system. Pallets are stored based on the expiration date, which varies by product.

Automated Storage and Retrieval Systems Methodology

Work on a system upgrade can normally be done over a weekend or during plant shut downs, when production is typically halted. The entirety of a project can normally be completed in a 3 to 6 month timeframe depending on the nature of the upgrade.

Though there are few regulatory requirements for warehouse systems, Grantek follows a rigorous project methodology to ensure that customer requirements are defined and met on schedule.

A typical Automated Storage and Retrieval Systems project consists of the following steps:

Gather customer requirements

Grantek analyzes the existing system and works with the customer to understand their goals for the upgrade. Factors such as increasing warehouse size, changes in product mix and product volumes, equipment nearing end of life, facility security, additional loading docks, and many others must be considered when planning an upgrade or working to design a new ASRS.

Develop functional requirement specifications

The specifications are written based on the requirements. Specifications are detailed and measurable and define the quantity and type of equipment needed for each function, including scanners, labeling equipment, cranes and conveyor as well as monitoring equipment and interfaces to the ERP and other facility systems.

The requirements are given to the customer for review and discussion and design does not proceed until the customer approves the requirement specifications.

Program the system

Grantek sets up the system at our facility in order to simulate performance and ensure the design is robust. We test as much as possible in our simulated system to help prevent unexpected problems when it is time to install the equipment at the warehouse. We test data flow and communication as well as functionality and the routing logic.

Replace software and onsite equipment

To minimize the impact on production, upgrades are typically done over the weekend during normally scheduled downtime.

Upgrading an open-source system that uses off-the-shelf vision systems and components is easier than upgrading a proprietary system supplied by a single vendor. When offsite testing and simulation is complete, Grantek upgrades software and hardware in the warehouse. The installation is validated at each site based on each customer’s requirements and on how they store their information in their ERP.

Finish testing onsite and commission the system

After software and hardware has been installed, the system is brought back online for testing during limited production, to allow any problems to be quickly identified and corrected before bringing production back up to full speed.

Testing includes site monitoring of alarms or equipment jams. We provide a PC based system that displays system status and can include remote monitoring or the use of mobile devices. Alerts can be tailored to suit the facility’s needs and can be sent via audible alerts in the plant, email, and/or text messages to designated maintenance personnel.

Advantages of working with Grantek

Grantek has been performing ASRS system upgrades for many years. We have experience working with crane vendors and with general warehouse requirements. Grantek is familiar with a variety of industries and can adapt to their requirements. For example, we understand the unique requirements of food and beverage production systems, and the requirements of food storage and the importance of expiration dates and accurate tracking in and out of the warehouse. We also have extensive knowledge of SAP and other ERP systems that allows us to ensure our system obtains the right product data from the ERP and also provides the location and order fulfillment data needed by the ERP.

The entire project can be managed by Grantek, or we can work with the customer’s preferred vendor for aspects of warehouse construction, including crane vendors. Grantek always works with the crane vendor the customer prefers. We have done projects with many different types of cranes, and our years of experience allow us to connect our clients with a strong network of vendors.

Grantek provides complete specifications to the customer’s preferred electrical and mechanical contractors. This allows the customer to select their preferred vendor for the electrical and other trades; Grantek can work with anyone and we provide the specifications to the customer’s desired subcontractors. We use off-the-shelf components for communication with the conveyors, sensors, cameras, etc.

Grantek’s methodology and simple, open-source system allows upgrades and cutover easily and quickly. Using open-source software that will work with generic equipment makes it easier to meet challenging schedules and helps prevent obsolescence and forced upgrades.

Grantek provides a system or display that shows diagnostics information so customers can troubleshoot and perform equipment maintenance themselves, instead of requiring potentially costly service calls. The ASRS solutions Grantek delivers are more cost-effective than the competition. Many of our customers prefer something simple and easy to use, so we supply custom code we write to meet the customer’s requirements, instead of forcing the warehouse to work within the constraints of an expensive proprietary warehouse management software system. This allows our customized software to determine where pallets go based on exactly our customer’s facility and preferences.

Grantek’s Smart Manufacturing Practice offers experience with and knowledge of SQL and SAP data structures, and we have the programming and integration skills to integrate our customized opensource nonproprietary solutions with the warehouse ERP system, including SAP. We invite project managers, engineering managers, or plant managers to contact us for more information about our unique warehouse ASRS solutions. These solutions, like all Grantek solutions are built on a holistic approach with client collaboration, productivity and growth in mind.