Over time, a manufacturing facility can become a collection of disconnected data silos that impede efficient decision-making. Grantek understands that for a business to run well, its departments and systems must be connected, share data and use this data to generate actionable information. From the supply chain to shipping and distribution channels, data integration is imperative across the entire enterprise.

Grantek understands Business Systems because we understand business. Manufacturing Execution Systems(MES) can help maximize performance, increase productivity, reduce waste, ensure product quality, and increase efficiency in manufacturing operations. Today, MES implementation is necessary to remain competitive and meet regulatory requirements in production environments, especially in the Pharmaceutical and Food and Beverage sectors.

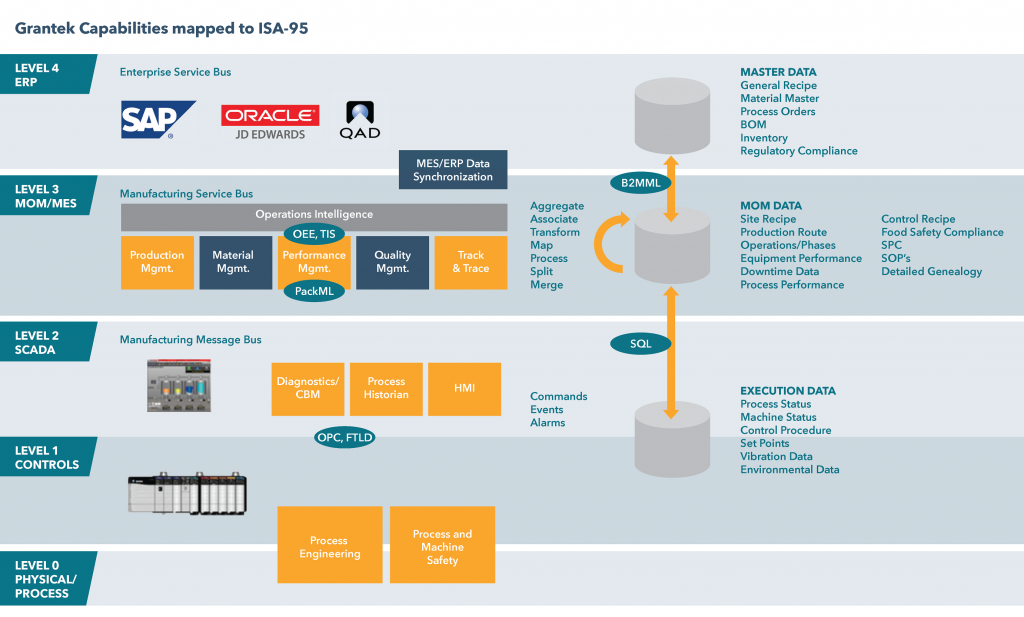

MES connects your low-level process control system (PLCs, SCADA, etc.) with the high-level Enterprise Resource Planning (ERP) system. Without MES, production environments merely consist of a collection of systems that operate independently from one another. MES provides the means for these systems to communicate with one another and enables operations personnel to make real-time, data-driven decisions.

We integrate all levels and technologies within your company; from allowing production orders and material master data to be available to the production floor via an MES/MOM system, therefore enabling automated recipe configuration and material validation; to reporting production counts from the floor up to the ERP system, reducing manual data entry and the possibility of human error.

MES provides the means for capturing production context data throughout the manufacturing process and can provide records required by the applicable regulatory agencies. MES software can maintain these records automatically as production occurs, enabling companies to quickly respond to regulatory audits and information requests. Grantek’s approach to MES implementations leverages the ISA-95 standard to build solutions based on accepted best practices.

As a Thought Leader in the industry, Grantek takes an active role in organizations like MESA, helping to develop standards and tools like B2MML (Business to Manufacturing Markup Language), an XML interpretation of ISA-95, which enables the integration of any MES/MOM system to any ERP system, allowing data to be shared where needed at all levels of the enterprise.

To ensure Business Systems are Integrated in a scalable, reliable way, Grantek takes a consultative approach, inspired by the GAMP-5 model and our own Project Management Methodology (PMM) . This ensures all requirements are accounted for throughout design and implementation phases. This consultative approach allows for a complete analysis up front, resulting in a reduction of unexpected costs down the road. This approach also considers the needs of all stakeholders, permitting Grantek to create a comprehensive system design, reducing the risks associated with implementing system changes in an unsystematic fashion.

As part of this process, we evaluate the current system and operations to fully understand and determine its true needs. We also understand how best to phase-in your integration project to reduce negative impacts to your on-going operations. Our methodology and capabilities, mapped to the ISA-95 standard, are shown in the following diagram.