OEE – Keys to Success

February 27, 2013

OEE is the simplest KPI. It measures how much stuff is made that can be sold vs. how much could have been made if everything was done right.

OEE is a key measure focused on equipment and process reliability improvement. It is a measure of how well we are capable of using our production equipment when we want them to operate. OEE is the product of three factors:

- Efficiency

- Availability

- Quality

There are three ways to reduce the cost of any automated process:

- Reduce unproductive machine time

- Reduce cycle times

- Reduce waste/scrap

In the OEE equation, we are seeking a higher OEE which means lower costs and higher profitability.

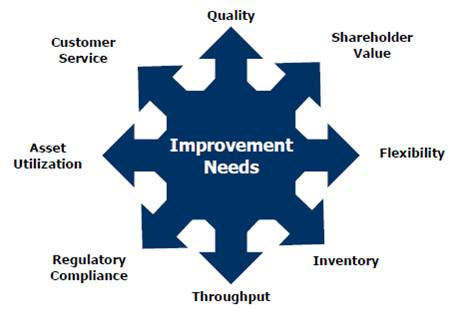

To achieve success in Overall Equipment Effectiveness (OEE), there are several areas you need to consider.

Check out the OEE Keys to Success Guide which will help you to leverage your investments in manufacturing automation and ERP to improve profitability and achieve operational excellence in manufacturing. The OEE Keys to Success Guide will help you to:

- Truly understand your KPIs and Metris that drives your business via a mapping engagement

- Understand how KPI and Metrics are going to influence behaviour

- Maximize MES or shop floor systems to track key manufacturing KPIs and improve operational performance

- Use ERP (or other financial systems) to track and report financial data by operation in as much detail as possible

- Analyze and determine correlation between operations and financial performance to find key manufacturing KPI linkage to business drivers