How Plant Safety Initiatives Positively Impact ROI

February 19, 2013

Machine Safety + Productivity = ROI

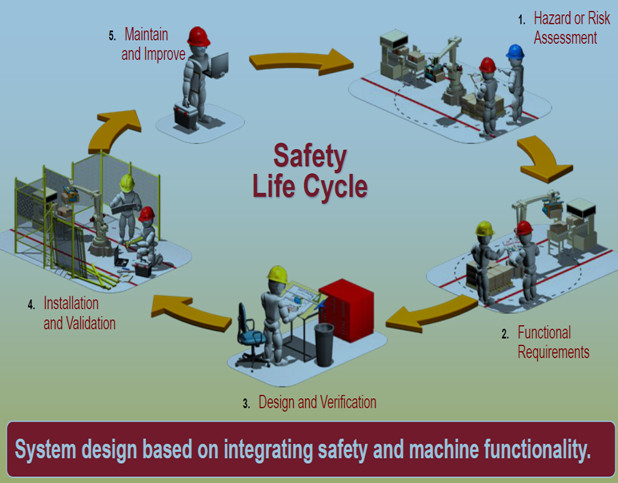

All manufacturers share a concern for employee safety and one very significant aspect of plant safety for your employees is machine safety. All of us want our employees to be as safe as possible while in a plant and while around manufacturing equipment. However, it is also important for employees and machines to be as productive as possible during each shift. Safety and productivity do not have be in opposition to each other. In fact, machine safety, if done well, can have positive impact on ROI!

Applied correctly, machine safety systems instill confidence in your employees. Proper line-of-sight resets are required in today’s standards and allow operators to resume production confidently, safely and more quickly after a stop. Multiply each time savings by the number of stops that occur in a large-scale manufacturing operation and there is a significant impact on your bottom line.

Similarly, knowing when to apply light curtains versus hard guarding can also provide increased productivity during a stoppage, repair, or maintenance cycle. Category 3 Safety Circuits are designed so that a single fault in any of its parts does not lead to the loss of safety function which provides redundancy in the safety circuit. Safety Rated PLC’s provide flexibility and cost savings for complex application with no loss to worker safety.

Another aspect of safety systems is installing them. Designing, installing, and commissioning safety systems with minimal impact on your operations is crucial. How can this be accomplished?

How to Get Strong ROI from Plant Safety Implementation

Ensuring that you partner with a manufacturing safety expert that will take the time to understand your operations, equipment, and seasonality of the demand for your products is the best step you can take to accomplish both your safety and ROI goals for your manufacturing operation. Your plant safety consultant should understand redundancies in your production and packaging lines. By taking the time to truly understand your manufacturing operations and look for opportunities to synchronize the design, installation, and commissioning phase of the safety effort with your scheduled operations, you can reduce or potentially eliminate increased machine down time while implementing safety to protect your employees.

Machine Safety Efforts Help Achieve Operational Excellence

By taking the necessary steps when designing, installing and commissioning your plant safety, your manufacturing operation can mean increased machine up time which produces strong ROI while ensuring a safe plant floor for your plant workers.

Download your Operational Excellence Blueprint which illustrates plant safety best practices. You can also sign up for our email newsletter to be the first to know when our Plant Safety Guide is released in Spring 2013.