The Drug Quality and Security Act, it’s impact on your manufacturing process.

January 31, 2017

Are you bringing your pharmaceutical facilities up to date for Serialization and Track & Trace? Is November of 2017 looming on your horizon? As you know, it is more than 2D barcodes. DQSA Compliance dates are critical, and coming fast. Grantek has been helping clients prepare and comply to the Drug Quality and Security Act since its passage in 2013 and is ready to help Pharma manufacturers meet Phase II of the Act, scheduled to begin Nov 21, 2017, which requires manufacturers to:

- Provide transaction information, history and transaction statements in electronic format

- Affix or imprint a product identifier to each package and case of product

- Verify at the package level, whether a suspect product is legitimate or not

- Respond within 24 hours to a request for verification

- Verify as legitimate returned products that are intended for resale

- Within two business days, provide the transaction information, statement and history to a request by the Secretary or other federal or state official.

Grantek has worked in the pharmaceutical and life sciences industry for over three decades and has a deep understanding of its operations and regulatory requirements, through our experience with different manufacturers, and the regulatory environment in which pharmaceutical manufacturers operate.

We do more than simply keeping up to date with regulatory standards and dates, we design, document, install, validate and commission 21cfr11 compliant facilities that meet those standards. At many facilities in multiple countries. Our clients count on us for:

- Solid dosing systems

- Liquid dosing systems

- Blending systems

- Batching systems

- CIP / SIP Systems

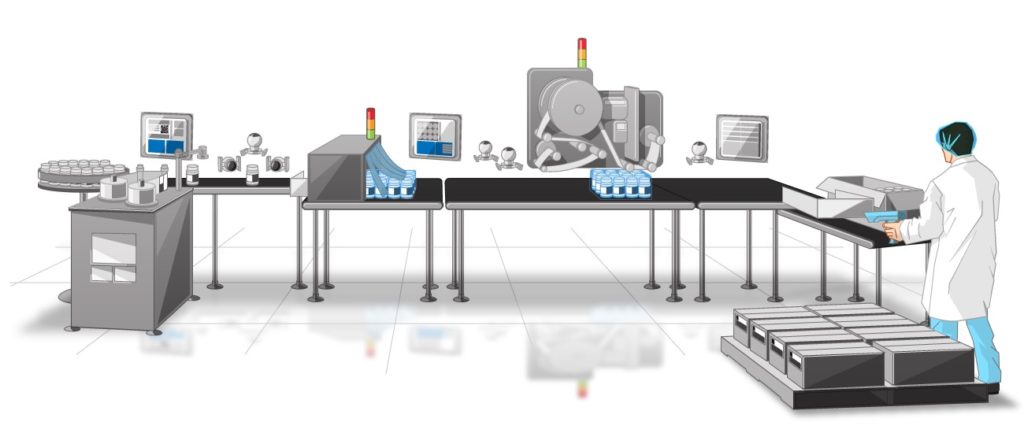

- Turnkey packaging lines

- BAS / BMS Systems

- RO Systems

Grantek has leveraged its serialization task force to provide both the strategy and successful execution of turnkey solutions that encompasses open standards such as EPICS to capture and share supply chain information about the movement and status of goods, both within their enterprise and with their business partners.

Grantek has implemented and integrated these solutions with many technology partners in control, Vision, Labeling and Printing and ERP and is an expert in leveraging these vendors in the most cost effective way.

Grantek uses smart manufacturing principles to design systems that can provide the backbone of serialization on pharmaceutical safety systems: traceability, absence of adulteration, label verification, and material management.

We have deep experience in all the technologies that need to be implemented, we understand the projection execution requirements for a pharmaceutical facility and we understand how to develop the system requirements for your exact needs.

Read more at:

https://grantek.com/case-study/cip/

https://grantek.com/industries/pharmalife-sciences/