Manufacturing Cloud – Environmental Monitoring in the Cloud – Part 1

February 6, 2013

Cloud-based Manufacturing Monitoring Provides Unique Opportunities to Monitor Critical Manufacturing Data

Cloud-based manufacturing monitoring affords companies some unique opportunities in dealing with the challenges of monitoring critical environmental data about both their manufacturing processes and their facilities. By leveraging the scalability, reliability, and flexibility that a cloud-based solution provides, a company can both enhance the features available to them, as well as improve the efficiency of the monitoring solution.

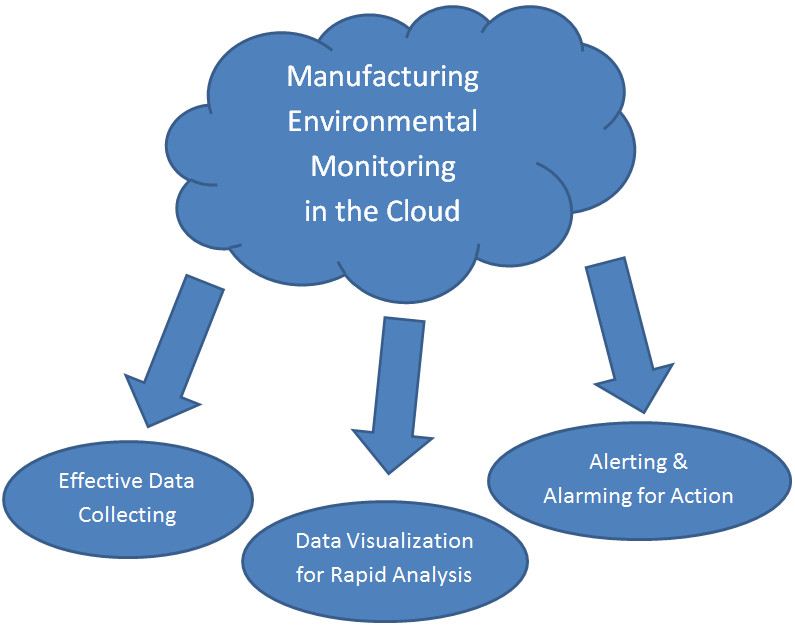

A cloud-based solution generally offers a more robust feature set then typical in-house options. It lets companies manage and access their manufacturing data whenever and how ever they need to, while lowering the effort required to maintain and monitor the solution. The manufacturing cloud makes an impact in three key areas:

- Effective data collecting,

- Data visualization for rapid analysis, and

- Alerting and alarming for appropriate action.

This blog will cover the art of effective data collection within the manufacturing cloud. Stay tuned for next week’s blog which dives into data visualization and alarming & alerting. You can sign up for our email newsletter on the right so you don’t miss it.

Manufacturing Cloud for Data Collection

In any deployment, the collection of data is the beginning of the monitoring process. It’s what drives the entire life cycle. Without a system that can effectively collect the manufacturing data that is required the usefulness of the system drops drastically.

Scalability

Cloud systems help reduce the cost associated with enterprise scale solutions. If you need to collect 2 or 2,000 data points, a manufacturing cloud solution offers the scalability a manufacturer needs at a cost they can afford. By utilizing a cloud solution that scales appropriately based on requirements, a manufacturer doesn’t have to worry about capacity planning, system optimization, or system efficiency. Time, energy, and money can be spent on growing their business and not on worrying or planning on how to grow their manufacturing monitoring system at the same rate.

Reliability

By employing a cloud-based monitoring system, a manufacturer can be confident that their critical environmental data is secure and accessible. The inherent connectivity of a cloud-based system provides access to the required manufacturing data whenever and where ever the client requires. Connectivity disruptions are handled by a redundant infrastructure design and security audits and monitoring are conducted to ensure that the critical data is always available and trustworthy.

Flexibility

When multiple data sources or instruments from different vendors are used, deploying a solution that integrates all the different data is critical. A single source in-house solution may not allow the use of more cost-effective or application-effective instruments. A cloud solution can collect and aggregate data from any number of instrument types, allowing the roll-out to be driven by the requirements of the environment being monitored and not what is supported by the in-house.

Manufacturing Cloud Allows Nimble and Flexible Access to Manufacturing Data

By using a manufacturing cloud solution to monitor environmental data, a company can rely on a solution that will offer them a platform that will scale with their business, and provide insight into their data in a nimble and flexible way. It helps companies focus on their business while not having to worry that their manufacturing monitoring solution will let them down.